Мерцедес показаха W07 (представяне)

Мерцедес показаха първите студийни снимки на новият си болид W07.

От няколко дни Мерцедес ни дразнят, като публикуват размазани снимки, случайно заснети кадри и кадри от филмовия си ден, но сега за първи път можем да видим и как изглежда W07 - болида им за сезон 2016 във Формула 1.

(авторски права на снимките - мерцедес)

(снимки от twitter)

Пади Лоу:

What were the main lessons learned from 2015 and how will these help the team progress in 2016?

PL: After a highly successful season all round in 2015, our priority has been to identify the areas in which we were weakest and to try to improve on those. Our objective is excellence in all areas and, while we had some fantastic results last year, there are many areas in which we can still be much better. That’s the kind of culture we try to instill throughout the whole organisation – one of constantly striving to reach something better. We had a number of races that didn’t go to plan in 2015 – Singapore in particular – so there were a lot of things that needed improving for 2016. We are seeking optimisation absolutely everywhere.

The rules for 2016 are relatively stable – have you gone for evolution or revolution with the new car?

PL: It’s difficult to have a complete revolution when the rules have stayed pretty much the same year on year. But we aim to make minor revolutions wherever we can – even within a small context. We may look at a completely new packaging solution or suspension concept, for instance. So, while the car may look very similar to its predecessor from the outside – as is inherent within stable regulations – underneath there are quite a lot of mini revolutions that make up an overall evolution for the new season.

Just how tough is it to find extra performance under stable regulations?

PL: It’s very tough to find performance under a stable set of regulations and we were particularly pleased with how the car turned out in 2015 when we had the same situation. The team did a fantastic job – digging very deep to find all sorts of innovations in areas that might have been considered static. 2016 is another carry-over year from a regulatory point of view and potential gains inevitably become harder to find under these circumstances. This is what tests an engineering team the most and I must say that this team has been very good at that. It’s far easier to find performance when you have a new set of rules, that’s for sure.

What are the major rule changes for 2016 that the team has been responding to?

PL: On the mechanical side, the main rule change is around the separate ducting of exhaust tail pipe and waste gate. But, in reality, that’s not had a major effect. The biggest structural change is on the chassis side, where we’ve raised the protection area around the driver by 20mm and increased the side impact test load from 15 to 50kN. This is a substantial increase in the load that has to be taken by the chassis as that point and will give much greater protection to the driver.

New concepts for 2016 will have minimal proving time on track with the reduction in winter testing. How big an impact will this have on preparations for the season ahead?

PL: The amount of testing permitted each season has been reduced progressively in recent years. We’ve now reached a new minimum in terms of winter testing, with two banks of four days. That’s something the team has been preparing for by producing better designs and undertaking better preparation and testing in the R&D lab so that we’re as well placed as possible to hit the ground running. What’s different for 2016 is actually not so much that there are only two tests – but that they’re both very close to the first race of the season. This has notably reduced the extent to which we can upgrade the car from ‘launch spec’ to the first race spec. That window is now very narrow, which reduces the number of potential upgrades ahead of the opening Grand Prix weekend.

Tyres will be the focus of attention, with a new compound and a change in the race weekend allocation format. How will this work and will be the impact?

PL: Firstly, there is now a new ultra soft compound tyre which we expect to see for the first time in Monaco. Generally, we’ve felt that even the soft and supersoft have been too hard for this circuit, so the ultrasoft will hopefully be a good solution there. The new regulation that allows three compounds per race appears quite complicated at first – but in practice it’s a lot simpler than it sounds! The intention is to create more uncertainty in the races – and I think where we’ll see that uncertainty is at those events where there is no definitive choice of compound for Sunday. We may see teams taking a gamble, which should produce more variation and some interesting races. Once again, a lot has been asked of Pirelli in terms of their contribution to the spectacle. They’ve done a great job in recent seasons and I’m sure that will continue with these new additions for 2016.

There has been much talk about a head protection device for introduction in the future. What is the status of this project?

PL: Since I first came into Formula One in the late eighties, the advancements in safety have been substantial. This has been particularly visible on the cars themselves, with the impact structures and load tests now in place – but also in other aspects of the sport, such as circuit design and facilities. However, as with every aspect of a car, there is always room for improvement. In my view, the driver’s head is the major risk remaining in Formula One and other forms of single-seater racing. We’ve seen quite a few near misses and, very sadly, some fatalities in recent years as a result of head injuries. A number of teams, including Mercedes, have strongly supported research into structures that could protect the drivers from such objects. This is a project which has been underway for several years and the motivation to pull this forward and reach a set of regulations as soon as possible has accelerated. There are a number of suggestions on the table and some of them look very realistic, so hopefully we may even see a solution appear for 2017.

PL: After a highly successful season all round in 2015, our priority has been to identify the areas in which we were weakest and to try to improve on those. Our objective is excellence in all areas and, while we had some fantastic results last year, there are many areas in which we can still be much better. That’s the kind of culture we try to instill throughout the whole organisation – one of constantly striving to reach something better. We had a number of races that didn’t go to plan in 2015 – Singapore in particular – so there were a lot of things that needed improving for 2016. We are seeking optimisation absolutely everywhere.

The rules for 2016 are relatively stable – have you gone for evolution or revolution with the new car?

PL: It’s difficult to have a complete revolution when the rules have stayed pretty much the same year on year. But we aim to make minor revolutions wherever we can – even within a small context. We may look at a completely new packaging solution or suspension concept, for instance. So, while the car may look very similar to its predecessor from the outside – as is inherent within stable regulations – underneath there are quite a lot of mini revolutions that make up an overall evolution for the new season.

Just how tough is it to find extra performance under stable regulations?

PL: It’s very tough to find performance under a stable set of regulations and we were particularly pleased with how the car turned out in 2015 when we had the same situation. The team did a fantastic job – digging very deep to find all sorts of innovations in areas that might have been considered static. 2016 is another carry-over year from a regulatory point of view and potential gains inevitably become harder to find under these circumstances. This is what tests an engineering team the most and I must say that this team has been very good at that. It’s far easier to find performance when you have a new set of rules, that’s for sure.

What are the major rule changes for 2016 that the team has been responding to?

PL: On the mechanical side, the main rule change is around the separate ducting of exhaust tail pipe and waste gate. But, in reality, that’s not had a major effect. The biggest structural change is on the chassis side, where we’ve raised the protection area around the driver by 20mm and increased the side impact test load from 15 to 50kN. This is a substantial increase in the load that has to be taken by the chassis as that point and will give much greater protection to the driver.

New concepts for 2016 will have minimal proving time on track with the reduction in winter testing. How big an impact will this have on preparations for the season ahead?

PL: The amount of testing permitted each season has been reduced progressively in recent years. We’ve now reached a new minimum in terms of winter testing, with two banks of four days. That’s something the team has been preparing for by producing better designs and undertaking better preparation and testing in the R&D lab so that we’re as well placed as possible to hit the ground running. What’s different for 2016 is actually not so much that there are only two tests – but that they’re both very close to the first race of the season. This has notably reduced the extent to which we can upgrade the car from ‘launch spec’ to the first race spec. That window is now very narrow, which reduces the number of potential upgrades ahead of the opening Grand Prix weekend.

Tyres will be the focus of attention, with a new compound and a change in the race weekend allocation format. How will this work and will be the impact?

PL: Firstly, there is now a new ultra soft compound tyre which we expect to see for the first time in Monaco. Generally, we’ve felt that even the soft and supersoft have been too hard for this circuit, so the ultrasoft will hopefully be a good solution there. The new regulation that allows three compounds per race appears quite complicated at first – but in practice it’s a lot simpler than it sounds! The intention is to create more uncertainty in the races – and I think where we’ll see that uncertainty is at those events where there is no definitive choice of compound for Sunday. We may see teams taking a gamble, which should produce more variation and some interesting races. Once again, a lot has been asked of Pirelli in terms of their contribution to the spectacle. They’ve done a great job in recent seasons and I’m sure that will continue with these new additions for 2016.

There has been much talk about a head protection device for introduction in the future. What is the status of this project?

PL: Since I first came into Formula One in the late eighties, the advancements in safety have been substantial. This has been particularly visible on the cars themselves, with the impact structures and load tests now in place – but also in other aspects of the sport, such as circuit design and facilities. However, as with every aspect of a car, there is always room for improvement. In my view, the driver’s head is the major risk remaining in Formula One and other forms of single-seater racing. We’ve seen quite a few near misses and, very sadly, some fatalities in recent years as a result of head injuries. A number of teams, including Mercedes, have strongly supported research into structures that could protect the drivers from such objects. This is a project which has been underway for several years and the motivation to pull this forward and reach a set of regulations as soon as possible has accelerated. There are a number of suggestions on the table and some of them look very realistic, so hopefully we may even see a solution appear for 2017.

Анди Коуел:

Mercedes has set the standard so far in the hybrid era. Where has the focus been over the winter to maintain that level of performance?

AC: It’s been more of the same. To get the performance out of this new generation of Power Units, you need to chase efficiency. That’s both combustion efficiency and efficiency in the various energy transition steps – i.e. MGU-H, MGU-K, turbocharger, power electronics and batteries. We’re constantly working on every single piece of the puzzle to improve performance at the crankshaft, while also seeking to ensure we don’t suffer any of the problems we had last year with reliability. So, it’s about getting down to the root cause of issues and making sure that everything is robust across our whole process, as much as extracting performance.

The technology in these Power Units is a story which has perhaps not been told as well as it could have been so far. Just how impressive are they?

AC: These Power Units really are incredible feats of engineering. We’re now running at more than 47% thermal efficiency and producing historic highs of power – and all with an ICE restricted to consuming fuel at a rate of just 100kg/hr. The old-fashioned, naturally aspirated engines peaked at 29% thermal efficiency during the V8 era – while the last time we saw these levels of power in Formula One was back in 2005, with a V10 that guzzled fuel at a whopping 194kg/hr. To halve the fuel flow rate for the same amount of power is quite something.

There are 32 tokens available to spend across the winter and during in-season development. What areas have been the focus of your development?

AC: 32 tokens is quite a lot, so we haven’t had to restrict any of our development activity to a specific area. Anything which could yield a decent efficiency improvement – and therefore a decent performance improvement – has been explored and we’re now working to make sure our package is sufficiently durable in time for Melbourne.

An extra two races on the calendar means an increased Power Unit allowance for the season ahead. How will this affect your approach to the season?

AC: On the face of it, an increased allocation of Power Units would seem to give manufacturers an advantage, in that each unit is required to complete fewer races, thereby putting less pressure on the life cycle of different components. But the reality is that our durability targets have remained the same. Our target is to make sure that each Power Unit can last for at least five races, meaning that theoretically we only need to use four per driver, across the season. We believe this gives us a good opportunity to react if we have a reliability problem – or potentially to use the extra units to our advantage for a performance enhancement at key races.

With in-season development for 2015 only confirmed late in the day, HPP were able to pull forward 2016 development work into the experimental engine introduced in Monza. How beneficial has that proven to be for all the teams running the Mercedes-Benz Power Unit in 2016?

AC: The upgrade that we introduced in Monza last year took a huge amount of effort from the factory at Brixworth and we only had enough resource to supply the works team with the latest spec at that time. However, that is now paying off for every team with Mercedes power, as we’ve managed to build on that development work through the autumn and winter period. Now, all our customers are getting an improved package that is exactly the same specification as the works team. All eight Mercedes powered cars will have exactly the same hardware and performance potential come Melbourne – which is a good step for everyone.

Fuel and lubricants were central to that development step. But how central will the role of PETRONAS be in finding yet more performance from the Power Unit?

AC: The rate of development from the Power Unit over the past two years has been very impressive. Many people thought that there was not much opportunity to move things forward – but that has not been the case. There have been significant new advances – and fuel and lubricants have been one of the main focus areas. Our 2015 mid-season update incorporated a sizeable step in fuel performance from PETRONAS. Then, later on in the year, we also introduced a new lubricant. We’ve made further progress in the way we’ve designed the combustion system and also enhanced the properties of the lubricants to reduce friction in the engine. PETRONAS are a key partner for us. They’re not just branding on the car – but a deep-rooted technology partnership. Anybody who designs engines knows that good fuel and lubricants are key to performance – and we’re very fortunate to have such a close and productive working relationship with PETRONAS.

Noise has been a hot topic since the new Power Unit formula was introduced in 2014. What’s changing in 2016 to pump up the volume and will this have any effect on performance?

AC: We’ve been conscious since the start of the Hybrid era in 2014 that the volume has diminished for those up in the grandstands as well as those watching at home. This is down to both the nature of a turbocharged engine and the recycling of waste energy in the exhaust system. The FIA therefore undertook an interesting and thorough investigation to analyse noise in the tailpipe and investigate what could be done to increase noise without impacting performance or efficiency. What they spotted is that the waste gate fed into the tailpipe. So, when the waste gate is not open, it’s a dead end. It then becomes a side branch resonator – or effectively a silencer – on the tailpipe. That design has now been removed, so we are left with a nice clean pipe without any silencing points, which should improve the noise of the Power Unit.

2016 sees a new face on the Mercedes-Benz Formula One customer roster – Manor Racing. How has that relationship been developing so far?

AC: Manor Racing is a new customer team for us this year. They’re a small team but a very efficient one, with a very pragmatic approach. We have a very detailed integration manual with instructions on how to fit the Power Unit, how best to use it and likewise what’s not recommended, so we’ve been working closely with them to ensure a seamless integration. They’ve been great to work with and we’re looking forward to seeing their progress through winter testing and into the season.

AC: It’s been more of the same. To get the performance out of this new generation of Power Units, you need to chase efficiency. That’s both combustion efficiency and efficiency in the various energy transition steps – i.e. MGU-H, MGU-K, turbocharger, power electronics and batteries. We’re constantly working on every single piece of the puzzle to improve performance at the crankshaft, while also seeking to ensure we don’t suffer any of the problems we had last year with reliability. So, it’s about getting down to the root cause of issues and making sure that everything is robust across our whole process, as much as extracting performance.

The technology in these Power Units is a story which has perhaps not been told as well as it could have been so far. Just how impressive are they?

AC: These Power Units really are incredible feats of engineering. We’re now running at more than 47% thermal efficiency and producing historic highs of power – and all with an ICE restricted to consuming fuel at a rate of just 100kg/hr. The old-fashioned, naturally aspirated engines peaked at 29% thermal efficiency during the V8 era – while the last time we saw these levels of power in Formula One was back in 2005, with a V10 that guzzled fuel at a whopping 194kg/hr. To halve the fuel flow rate for the same amount of power is quite something.

There are 32 tokens available to spend across the winter and during in-season development. What areas have been the focus of your development?

AC: 32 tokens is quite a lot, so we haven’t had to restrict any of our development activity to a specific area. Anything which could yield a decent efficiency improvement – and therefore a decent performance improvement – has been explored and we’re now working to make sure our package is sufficiently durable in time for Melbourne.

An extra two races on the calendar means an increased Power Unit allowance for the season ahead. How will this affect your approach to the season?

AC: On the face of it, an increased allocation of Power Units would seem to give manufacturers an advantage, in that each unit is required to complete fewer races, thereby putting less pressure on the life cycle of different components. But the reality is that our durability targets have remained the same. Our target is to make sure that each Power Unit can last for at least five races, meaning that theoretically we only need to use four per driver, across the season. We believe this gives us a good opportunity to react if we have a reliability problem – or potentially to use the extra units to our advantage for a performance enhancement at key races.

With in-season development for 2015 only confirmed late in the day, HPP were able to pull forward 2016 development work into the experimental engine introduced in Monza. How beneficial has that proven to be for all the teams running the Mercedes-Benz Power Unit in 2016?

AC: The upgrade that we introduced in Monza last year took a huge amount of effort from the factory at Brixworth and we only had enough resource to supply the works team with the latest spec at that time. However, that is now paying off for every team with Mercedes power, as we’ve managed to build on that development work through the autumn and winter period. Now, all our customers are getting an improved package that is exactly the same specification as the works team. All eight Mercedes powered cars will have exactly the same hardware and performance potential come Melbourne – which is a good step for everyone.

Fuel and lubricants were central to that development step. But how central will the role of PETRONAS be in finding yet more performance from the Power Unit?

AC: The rate of development from the Power Unit over the past two years has been very impressive. Many people thought that there was not much opportunity to move things forward – but that has not been the case. There have been significant new advances – and fuel and lubricants have been one of the main focus areas. Our 2015 mid-season update incorporated a sizeable step in fuel performance from PETRONAS. Then, later on in the year, we also introduced a new lubricant. We’ve made further progress in the way we’ve designed the combustion system and also enhanced the properties of the lubricants to reduce friction in the engine. PETRONAS are a key partner for us. They’re not just branding on the car – but a deep-rooted technology partnership. Anybody who designs engines knows that good fuel and lubricants are key to performance – and we’re very fortunate to have such a close and productive working relationship with PETRONAS.

Noise has been a hot topic since the new Power Unit formula was introduced in 2014. What’s changing in 2016 to pump up the volume and will this have any effect on performance?

AC: We’ve been conscious since the start of the Hybrid era in 2014 that the volume has diminished for those up in the grandstands as well as those watching at home. This is down to both the nature of a turbocharged engine and the recycling of waste energy in the exhaust system. The FIA therefore undertook an interesting and thorough investigation to analyse noise in the tailpipe and investigate what could be done to increase noise without impacting performance or efficiency. What they spotted is that the waste gate fed into the tailpipe. So, when the waste gate is not open, it’s a dead end. It then becomes a side branch resonator – or effectively a silencer – on the tailpipe. That design has now been removed, so we are left with a nice clean pipe without any silencing points, which should improve the noise of the Power Unit.

2016 sees a new face on the Mercedes-Benz Formula One customer roster – Manor Racing. How has that relationship been developing so far?

AC: Manor Racing is a new customer team for us this year. They’re a small team but a very efficient one, with a very pragmatic approach. We have a very detailed integration manual with instructions on how to fit the Power Unit, how best to use it and likewise what’s not recommended, so we’ve been working closely with them to ensure a seamless integration. They’ve been great to work with and we’re looking forward to seeing their progress through winter testing and into the season.

Mercedes-Benz F1 W07 Hybrid Technical Specification

Chassis

Monocoque: Moulded carbon fibre and honeycomb composite structure

Bodywork: Carbon fibre composite including engine cover, sidepods, floor, nose, front wing and rear wing

Cockpit: Removable driver's seat made of anatomically formed carbon composite, Sabelt six-point driver safety harness, HANS system

Safety Structures: Cockpit survival cell incorporating impact resistant construction and penetration panels, front impact structure, prescribed side impact structures, integrated rear impact structure, front and rear roll structures

Front Suspension: Carbon fibre wishbone and pushrod activated torsion springs and rockers

Rear Suspension: Carbon fibre wishbone and pullrod activated torsion springs and rockers

Wheels: Advanti forged magnesium

Tyres: Pirelli

Brake System: Carbon / carbon discs and pads with rear brake-by-wire

Brake Calipers: Brembo

Steering: Power assisted rack and pinion

Steering Wheel: Carbon-fibre construction

Electronics: FIA standard ECU and FIA homologated electronic and electrical system

Instrumentation: McLaren Electronic Systems (MES)

Fuel System: ATL Kevlar-reinforced rubber bladder

Lubricants & Fluids: PETRONAS Tutela

Transmission

Gearbox: Eight-speed forward, one reverse unit with carbon fibre maincase

Gear Selection: Sequential, semi-automatic, hydraulic activation

Clutch: Carbon plate

Dimensions

Overall Length: 5000mm

Overall Width: 1800mm

Overall Height: 950mm

Overall Weight: 702kg

Mercedes-Benz PU106C Hybrid Technical Specification

Power Unit Specification

Type: Mercedes-Benz PU106C Hybrid

Minimum Weight: 145 kg

Power Unit Perimeter: Internal Combustion Engine (ICE)

Motor Generator Unit - Kinetic (MGU-K)

Motor Generator Unit - Heat (MGU-H)

Turbocharger (TC)

Energy Store (ES)

Control Electronics (CE)

Power Unit Allocation: Four Power Units per driver per season

(increased to five if calendar exceeds 20 races)

Internal Combustion Engine (ICE)

Capacity: 1.6 litres

Cylinders: Six

Bank Angle: 90

No of Valves: 24

Max rpm ICE: 15,000 rpm

Max Fuel Flow Rate: 100 kg/hour (above 10,500 rpm)

Fuel Injection: High-pressure direct injection (max 500 bar, one injector/cylinder)

Pressure Charging: Single-stage compressor and exhaust turbine on a common shaft

Max rpm Exhaust Turbine: 125,000 rpm

Energy Recovery System (ERS)

Architecture: Integrated Hybrid energy recovery via electrical Motor Generator Units

Energy Store: Lithium-Ion battery solution of 20 kg regulation weight

Max energy storage/lap: 4 MJ

Max rpm MGU-K: 50,000 rpm

Max power MGU-K: 120 kW (161 hp)

Max energy recovery/lap MGU-K: 2 MJ

Max energy deployment/lap MGU-K: 4 MJ (33.3 s at full power)

Max rpm MGU-H: 125,000 rpm

Max power MGU-H: Unlimited

Max energy recovery/lap MGU-H: Unlimited

Max energy deployment/lap MGU-H: Unlimited

Fuel & Lubricants

Fuel: PETRONAS Primax

Lubricants: PETRONAS Syntium

Още от сезон 2016:

- Тестове в Бахрейн 19.04.2017 (снимки)

- Връчване на титлите в шампионатите на FIA (снимки)

- След шампионската титла Нико Розберг в Куала Лумпур и Бракли (снимки, видео)

- Нико Розберг се оттегля от Формула 1

- Пирели тестват гуми за 2017 в Абу Даби (снимки)

- Абу Даби 2016 - резултати от прогнозите (игра)

- Абу Даби 2016 - неделя (снимки)

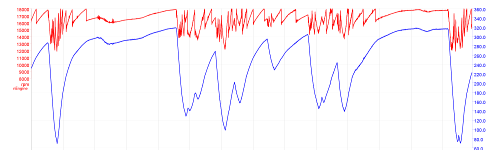

- Абу Даби 2016 - разлики по обиколки (графика)

- Абу Даби 2016 - обиколки (графика)

- Абу Даби 2016 - позиции (графика)

Все още няма коментари

Нов коментар

Само регистрирани потребители могат да коментират. Ако вече имате регистрация можете да влезете в сайта от "Вход". В противен случай можете да се регистирате като натиснете "Вход" и избере "Регистрация". За повече информация: f1.f-e-n.net/index.php/url14729

.jpg)

Коментари