МакЛарън MP4/31 (представяне)

Ето го и новият болид на МакЛарън за сезон 2016 - MP4/31.

Снимки на болида се появиха късно снощи и въпреки, че представянето беше обявено за 12:00 днес, то МакЛарън изпревариха себе си и пуснаха снимки на болида си по пощата почти час и половина по-рано.

(авторски права на снимките - МакЛарън)

Фернандо Алонсо:

Тhe start of a new season is always a special feeling, characterised by a lot of anticipation for the year ahead. This year is no different: I’m excited and raring to go.

Last year the spotlight was very much on McLaren-Honda as we embarked on the first year of our renewed partnership. It was a tricky season for all of us, but we learned a hell of a lot.

Likewise, it’s been a very productive winter for me. I’ve been training extremely hard, as usual, but also enjoying time with my family, and keeping tabs on all the hard work going on at the McLaren Technology Centre, Woking, where the McLaren guys have been doing an incredible job to get everything ready in time. The Honda boys have been working flat-out in Sakura, too.

The aero package shows fantastic attention to detail. The whole car is beautiful in fact – it’s particularly nicely packaged from an aerodynamic point of view as I say – and I’m 100 per cent ready for the challenge ahead.

Last year the spotlight was very much on McLaren-Honda as we embarked on the first year of our renewed partnership. It was a tricky season for all of us, but we learned a hell of a lot.

Likewise, it’s been a very productive winter for me. I’ve been training extremely hard, as usual, but also enjoying time with my family, and keeping tabs on all the hard work going on at the McLaren Technology Centre, Woking, where the McLaren guys have been doing an incredible job to get everything ready in time. The Honda boys have been working flat-out in Sakura, too.

The aero package shows fantastic attention to detail. The whole car is beautiful in fact – it’s particularly nicely packaged from an aerodynamic point of view as I say – and I’m 100 per cent ready for the challenge ahead.

Дженсън Бътън:

I really can’t wait to take the wheel of the new MP4-31 tomorrow. All Formula 1 drivers need a winter break, but I’m massively excited to get started on the 2016 season now, and I have to say the brand-new McLaren-Honda MP4-31 really looks the part.

Moreover, having spent quite a bit of time at the McLaren Technology Centre recently, I can tell you that there’s a huge amount of palpable positive energy there at the moment, despite the challenging yet steep learning curve we all travelled along in 2015.

In fact, the immense amount of sheer hard work that has gone into the development of the MP4-31 over the winter makes me immensely proud, and consequently I go into the new season with even more motivation and belief.

Despite the ups and downs we saw last year, there were steady improvements all year long, and that gives us confidence in the design direction we’re taking. There are a lot of positives we can build on, and a strong platform to take forward. I’m not about to make any over-optimistic predictions – Formula 1 is far too unpredictable for me to do that – but, from what I’ve seen so far, the aero detailing on the car looks fantastic, and I’m really looking forward to beginning the process of testing those new innovations when I get behind the wheel tomorrow.

Moreover, having spent quite a bit of time at the McLaren Technology Centre recently, I can tell you that there’s a huge amount of palpable positive energy there at the moment, despite the challenging yet steep learning curve we all travelled along in 2015.

In fact, the immense amount of sheer hard work that has gone into the development of the MP4-31 over the winter makes me immensely proud, and consequently I go into the new season with even more motivation and belief.

Despite the ups and downs we saw last year, there were steady improvements all year long, and that gives us confidence in the design direction we’re taking. There are a lot of positives we can build on, and a strong platform to take forward. I’m not about to make any over-optimistic predictions – Formula 1 is far too unpredictable for me to do that – but, from what I’ve seen so far, the aero detailing on the car looks fantastic, and I’m really looking forward to beginning the process of testing those new innovations when I get behind the wheel tomorrow.

Рон Денис:

As we embark on the second year of our renewed McLaren-Honda partnership, all of us remain united in our purpose. That purpose is to develop our team towards our shared ambition: to win.

We’ll make no predictions as to when those wins will come, but I can say without fear of contradiction that every member of our team has worked with truly relentless dedication over the past few months. The result is that MP4-31’s developmental trajectory has been usefully steepened over the winter, and I’m consequently very proud of our team’s efforts.

We remain resolute in our commitment to our goals, and we maintain an indefatigable commitment to the winning potential of a full works team. Believe me: the full works backing of a multinational automotive manufacturer is the only platform from which real success in modern Formula 1 can be achieved. As McLaren-Honda, therefore, we’ve vowed to work together, and to win together, and that determination has become further cemented as our relationship has deepened through the shared challenges we faced last year.

We have the best driver line-up in the sport. We have an engineering team that has been meticulously hand-picked, restructured, guided and inspired; the blend of technical skill-sets and attitudinal mind-sets we now possess are fit-for-purpose and state-of-the-art. And, thanks to the relationships we’ve nurtured with a hugely impressive roster of loyal and powerful partners, our commercial position is equally robust.

We’ll make no predictions as to when those wins will come, but I can say without fear of contradiction that every member of our team has worked with truly relentless dedication over the past few months. The result is that MP4-31’s developmental trajectory has been usefully steepened over the winter, and I’m consequently very proud of our team’s efforts.

We remain resolute in our commitment to our goals, and we maintain an indefatigable commitment to the winning potential of a full works team. Believe me: the full works backing of a multinational automotive manufacturer is the only platform from which real success in modern Formula 1 can be achieved. As McLaren-Honda, therefore, we’ve vowed to work together, and to win together, and that determination has become further cemented as our relationship has deepened through the shared challenges we faced last year.

We have the best driver line-up in the sport. We have an engineering team that has been meticulously hand-picked, restructured, guided and inspired; the blend of technical skill-sets and attitudinal mind-sets we now possess are fit-for-purpose and state-of-the-art. And, thanks to the relationships we’ve nurtured with a hugely impressive roster of loyal and powerful partners, our commercial position is equally robust.

Ерик Булие:

First of all, we must recognise the very hard work performed over the past few months by everyone in Woking, Sakura and Milton Keynes.

The guys have shown intense dedication throughout the winter period, and the result is that they’ve successfully kept our aggressive build and development programmes on schedule. As such, all our team members are a credit to McLaren-Honda, and consequently we’re incredibly grateful to everyone involved in the development of the MP4-31.

But we’re never satisfied, which is why we’ve continued to strengthen our engineering team in recent weeks and months, and we’re confident that the changes we’ve made will improve and accelerate our car-development progress in the future.

So the two Barcelona tests will merely herald the continuation of the huge collaborative task that all departments have been engaged in during the off-season. We’ll be aiming to spend the four days of the first test carefully and methodically: extracting the maximum from the time available, and concentrating our efforts on proving out our central systems, operational procedures and electronics checks. We’ll need to verify our work in the garage before we can expect any miracles on track – essentially, to ensure we walk before we can run. After all, testing is just that: testing.

But be assured, we’re motivated and determined, and we’re pulling together.

The guys have shown intense dedication throughout the winter period, and the result is that they’ve successfully kept our aggressive build and development programmes on schedule. As such, all our team members are a credit to McLaren-Honda, and consequently we’re incredibly grateful to everyone involved in the development of the MP4-31.

But we’re never satisfied, which is why we’ve continued to strengthen our engineering team in recent weeks and months, and we’re confident that the changes we’ve made will improve and accelerate our car-development progress in the future.

So the two Barcelona tests will merely herald the continuation of the huge collaborative task that all departments have been engaged in during the off-season. We’ll be aiming to spend the four days of the first test carefully and methodically: extracting the maximum from the time available, and concentrating our efforts on proving out our central systems, operational procedures and electronics checks. We’ll need to verify our work in the garage before we can expect any miracles on track – essentially, to ensure we walk before we can run. After all, testing is just that: testing.

But be assured, we’re motivated and determined, and we’re pulling together.

Ясухиса Арай:

From the start of tomorrow’s testing, the second season of McLaren-Honda’s new adventure begins. It was a short winter break, but nonetheless Honda was able to make the most of the off-season in preparation for 2016, strengthening our team and working tirelessly alongside the McLaren and ExxonMobil engineers.

Learning from last year, we’ve made changes to the compressor and other hardware of the power unit during the break, maturing our overall concept from last year. Our focus will be to test the car’s balance with the new chassis and power unit, and specifically the ERS direction during the eight days of winter testing.

We won’t know exactly where we stand until we reach the end of the two tests, but we’re looking forward to getting back on track, gathering data, and feeding back the information to our engineers so as to prepare for Melbourne and onwards.

It’s good to be back.

Learning from last year, we’ve made changes to the compressor and other hardware of the power unit during the break, maturing our overall concept from last year. Our focus will be to test the car’s balance with the new chassis and power unit, and specifically the ERS direction during the eight days of winter testing.

We won’t know exactly where we stand until we reach the end of the two tests, but we’re looking forward to getting back on track, gathering data, and feeding back the information to our engineers so as to prepare for Melbourne and onwards.

It’s good to be back.

Monocoque: Carbon-fibre composite, incorporating driver controls and fuel cell

Safety structures: Cockpit survival cell incorporating impact resistant construction and anti-penetration panels, front impact structure, prescribed side impact structures, integrated rear impact structure, front and rear roll structures

Bodywork: Carbon-fibre composite, including engine cover, sidepods, floor, nose, front wing and rear wing with driver-operated drag reduction system

Front suspension: Carbon-fibrewishbone and pushrod suspension elements operating inboard torsion bar and damper system

Rear suspension: Carbon-fibrewishbone and pullrod suspension elements operating inboard torsion bar and damper system

Weight: Overall vehicle weight 702kg (including driver, excluding fuel)

Weight distribution: between 45.5% and 46.5%

Electronics: McLaren Applied Technologies. Including chassis control, power unit control, data acquisition, sensors, data analysis and telemetry

Instruments: McLaren Applied Technologies dashboard

Greases & Fluids: Mobilith SHC™ 1500 Grease – High temperature drive-shaft tripod lubrication

Mobilith SHC™ 220 Grease – Low rolling resistance ceramic wheel bearing lubrication

Mobil SHC™ Hydraulic Oil – High pressure, high temperature hydraulic fluid used for chassis, transmission and power unit actuation

Brake system: Akebono brake calipers and master cylinders

Akebono ‘brake by wire’ rear brake control system

Carbon discs and pads

Steering: Power-assisted rack and pinion

Tyres: Pirelli P Zero

Race wheels: Enkei

Garage Radio: Kenwood

Paint: AkzoNobel Car Refinishes system using Sikkens products

Power Unit

Type: HONDA RA616H

Minimum weight: 145 kg

Primary PU components: Internal Combustion Engine (ICE)

Motor Generator Unit – Kinetic (MGU-K)

Motor Generator Unit – Heat (MGU-H)

Energy Store (ES)

Turbocharger

Control Electronics

Internal Combustion Engine

Capacity: 1.6 litres

Cylinders: Six

Bank angle: 90 degree vee angle

No of valves: 24

Max speed: 15,000 rpm

Max fuel flow rate: 100 kg/hour (above 10,500 rpm)

Fuel consumption: 100 kg ‘lights to flag’ regulated fuel capacity limit

Fuel injection: Direct injection, single injector per cylinder, 500 bar max

Pressure charging: Single-stage compressor and exhaust turbine, common shaft

Fuel: Esso™ High Performance Unleaded Race Fuel (5.75% bio fuel)

Lubricant: Mobil 1™ Racing Oil – High protection low friction lubricant for high durability and improved fuel economy

Energy Recovery System

Architecture: Integrated Hybrid energy recovery via Motor Generator Units

Crankshaft coupled electrical MGU-K

Turbocharger coupled electrical MGU-H

Energy Store: Lithium-Ion battery, between 20 and 25 kg

Maximum energy storage, 4 MJ per lap

MGU-K: Maximum speed, 50,000 rpm

Maximum power, 120 kW

Maximum energy recovery, 2 MJ per lap

Maximum energy deployment, 4 MJ per lap

MGU-H: Maximum speed 125,000 rpm

Maximum power, unlimited

Maximum energy recovery, unlimited

Maximum energy deployment, unlimited

Transmission

Gearbox: Carbon-fibre composite main case, longitudinally mounted

Gear ratios: Eight forward and one reverse

Gear selection: Electro-hydraulically operated seamless shift

Differential: Epicyclic differential withmulti-platelimited slipclutch

Clutch: Electro-hydraulically operated, carbon multi-plate

Lubricant: Mobilube 1 SHC™ Racing Gear Oil – Low traction loss, high efficiency gear and bearing lubricant and coolant

Още от сезон 2016:

- Тестове в Бахрейн 19.04.2017 (снимки)

- Връчване на титлите в шампионатите на FIA (снимки)

- След шампионската титла Нико Розберг в Куала Лумпур и Бракли (снимки, видео)

- Нико Розберг се оттегля от Формула 1

- Пирели тестват гуми за 2017 в Абу Даби (снимки)

- Абу Даби 2016 - резултати от прогнозите (игра)

- Абу Даби 2016 - неделя (снимки)

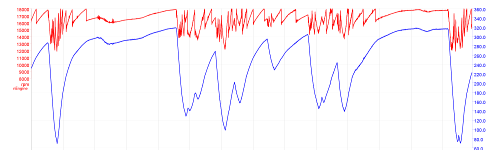

- Абу Даби 2016 - разлики по обиколки (графика)

- Абу Даби 2016 - обиколки (графика)

- Абу Даби 2016 - позиции (графика)

Все още няма коментари

Нов коментар

Само регистрирани потребители могат да коментират. Ако вече имате регистрация можете да влезете в сайта от "Вход". В противен случай можете да се регистирате като натиснете "Вход" и избере "Регистрация". За повече информация: f1.f-e-n.net/index.php/url14729

.jpg)

Коментари